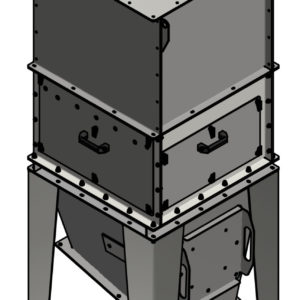

Description

- Modular construction with standard size

- Weigher’s mount made of welded steel sections

- Weighing bin from 3-4 mm thick steel plate

- 4-6 DMS load cells with elastomer bearing used as load transfer elements

- sight glasses on the front end

- The top cover of the bin is segmented and bolted to the weigher’s mount, and water-tight neoprene canopy between the feeders and the weighing bin. Size of the inlet ports as per customer’s requirements.

- Cable terminal box

- Sideway movements taken up by Suspension arms

- Inspection flap 1 pc bolted on, with no status indicator

- Bulk product: floury, powdery, and granular feed ingredients

- Flow properties: 0,5 – 0,75 t / cbm

- Flow properties: dry, free-flowing

- Ambient temperature: Max. 40°C/104°F

- Operating rooms: Normal industrial settings

- Requirements: Inbuilt, ready-to-plug, electric system with wired socket box

- Weight range: 500 – 5.000 kg

- Weighing bin: with cross brace reinforcement and connection flanges for easy handling and transportation, and dust/powder-proof inspection hatch

- Bin size: Weighing bin made from standard components Length adjustable by 900 mm steps

- Total length: 1800 – 9000 mm (longer versions are possible on request)

- Width of (supply) inlet: always 1500 mm

- Width of (discharge) outlet: always 950 mm

- Height: 1.400 mm

- Discharge system: connection flange to the flat-plate gate-valve, or chain conveyor

- Product supply: through a fixed cover bolted to the weigher’s mount, with adjustable gaskets and surrounding dust cover for Trellex joints

- Optional:

- Pneumatic sliding frame

- with push-floor discharging technology

- made from ST37 steel in a bolted, or welded variant

- The sliding plate is mounted on ball bearing rails and equipped

- with adjustable cylinder switch

- capacity proximity switch for the „on/off“ control of the end position

- All sliding plates are sheltered under a roof

- Transfer to the discharge funnel with Trellex joints and neoprene canopy